Tesla Mechanical Designs Accelerates Sheet Metal Manufacturing with Smart CAD Processes

Advanced CAD workflows reduce prototyping cycles, optimize material usage, and streamline production for faster time-to-market delivery.

𝐀𝐜𝐜𝐞𝐥𝐞𝐫𝐚𝐭𝐞𝐝 𝐏𝐫𝐨𝐭𝐨𝐭𝐲𝐩𝐢𝐧𝐠 𝐚𝐧𝐝 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧

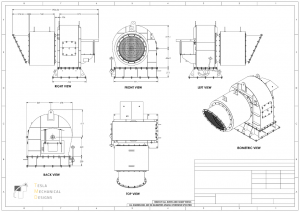

A significant differentiator for Tesla Mechanical Design is its capability to compress prototyping and production timelines dramatically. The company's specialized expertise in CAD for sheet metal goes beyond mere design creation; it is about optimizing every phase of the manufacturing process from its beginning.

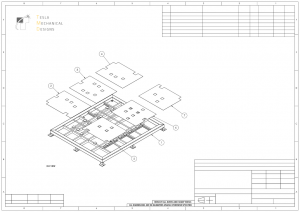

Historically, the manual generation of flat patterns and the intricate process of manufacturability analysis have been major bottlenecks in sheet metal fabrication. Such manual efforts are prone to errors, leading to costly reworks and schedule delays. Tesla Mechanical Design's sophisticated CAD systems automate flat pattern generation with exceptional accuracy, instantly translating complex 3D models into precise 2D layouts ready for immediate cutting and forming. This automation drastically minimizes human error, freeing up significant time traditionally spent on design iteration and preparation.

Moreover, the CAD processes employed by Tesla Mechanical Design embed advanced manufacturability analysis tools. These tools are designed to proactively identify potential issues such as bending clashes, material thinning, or excessive deformation, long before any physical prototype is even considered. By simulating manufacturing processes digitally, the company can refine designs for optimal fabrication, reducing the need for costly design modifications during actual production and ensuring the final product consistently meets exact specifications. This predictive capability directly translates into fewer prototype iterations, faster validation, and a smoother transition to full-scale manufacturing.

For clients, this translates into a significant reduction in time-to-market. Processes that once consumed weeks or months for prototyping and testing can now be accomplished in a fraction of that time. This agility allows companies to respond more rapidly to market demands, secure a competitive edge, and innovate at an accelerated pace. Tesla Mechanical Design's streamlined approach ensures that projects move from initial concept to tangible product quickly and confidently. “By digitally simulating manufacturing processes before physical production, we've reduced prototype iterations by up to 40% while ensuring first-time manufacturing success.” said Prex Poojara, Director at Tesla Mechanical Designs.

𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐞𝐝 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐑𝐮𝐧𝐬 𝐰𝐢𝐭𝐡 𝐨𝐮𝐫 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐭 𝐂𝐀𝐃 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐞𝐬

Beyond just speed, Tesla Mechanical Design’s commitment to CAD delivers exceptional precision and efficiency, directly influencing operational costs and environmental footprint. Material waste is a pervasive and costly concern in sheet metal fabrication. The CAD processes implemented by the company are meticulously designed to mitigate this challenge.

The software utilized by Tesla Mechanical Design incorporates advanced nesting algorithms that intelligently arrange flat patterns on raw sheet metal. This ensures the most efficient use of material, achieving higher utilization rates, significantly reducing scrap, and lowering material costs. This is not only about financial savings but also about fostering sustainable manufacturing practices by minimizing waste generation.

Furthermore, Tesla Mechanical Design's CAD processes inherently optimize production runs. By ensuring designs are inherently manufacturable from the outset, the company significantly reduces the likelihood of expensive errors or delays on the production floor. The precision of its generated flat patterns and bending instructions produces fewer rejected parts, less rework, and a more fluid, efficient manufacturing flow. Every cut, bend, and form is meticulously calculated and digitally verified, leading to consistently high-quality output.

This level of precision extends to the final product, ensuring components fit together seamlessly and assemblies meet the highest quality and functionality standards. By minimizing material waste and optimizing production, Tesla Mechanical Design helps businesses achieve greater profitability and operational excellence while contributing to more sustainable manufacturing practices.

𝐒𝐞𝐚𝐦𝐥𝐞𝐬𝐬 𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧: 𝐀 𝐔𝐧𝐢𝐟𝐢𝐞𝐝 𝐃𝐞𝐬𝐢𝐠𝐧-𝐭𝐨-𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐖𝐨𝐫𝐤𝐟𝐥𝐨𝐰

The true strength of Tesla Mechanical Design’s approach lies in its ability to forge a seamlessly integrated workflow, effectively bridging the gap between design and production. The traditional separation between CAD and CAM (Computer-Aided Manufacturing) systems can often lead to compatibility issues, data loss, and additional manual interventions, slowing down the entire process. Tesla Mechanical Design's solutions eliminate these common friction points.

Tesla Mechanical Design's advanced CAD systems are engineered for direct and effortless integration with CAM systems. Once a design is finalized in its CAD environment, all necessary manufacturing data—such as toolpaths for cutting machines or detailed bending instructions for press brakes—can be directly exported without manual intervention or data translation errors. This streamlined data transfer ensures that the design's integrity is maintained throughout the entire process, from initial concept to the final manufactured part.

This seamless integration facilitates a smooth transition from digital design to physical product. It removes the necessity for manual machine programming based on 2D drawings, which is often time-consuming and error-prone. Instead, the optimized design data flows directly to the manufacturing equipment, enabling automated production with minimal setup time. This holistic approach accelerates time-to-market, enhances overall production efficiency, reduces operational costs, and ensures consistent product quality.

Tesla Mechanical Design empowers businesses to achieve genuine manufacturing agility by championing this unified design-to-production workflow. Its clients can adapt swiftly to market changes, iterate on designs easily, and move into production with confidence, ensuring that every step is optimized for speed, precision, and cost-effectiveness. This comprehensive integration is foundational for modern, efficient, competitive sheet metal manufacturing.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧

Tesla Mechanical Design is an innovative engineering design and automation firm that enhances manufacturing processes through intelligent design and advanced technological solutions. Specializing in mechanical design with a strong emphasis on CAD for sheet metal, the company empowers businesses to achieve new levels of efficiency, precision, and speed in their product development and production cycles. Its expertise helps clients accelerate prototyping, minimize material waste, and streamline their journey from initial concept to successful market launch. For more information on how Tesla Mechanical Design can transform your manufacturing capabilities, please visit its website at www.teslamechanicaldesigns.com | On-Demand Custom Manufacturing - https://www.teslamechanicaldesigns.com/manufacturing-services.php

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

X

Other

Distribution channels: Business & Economy, Companies, Manufacturing, Technology, World & Regional

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release